BMW B58 Engine Oil Pump Issues

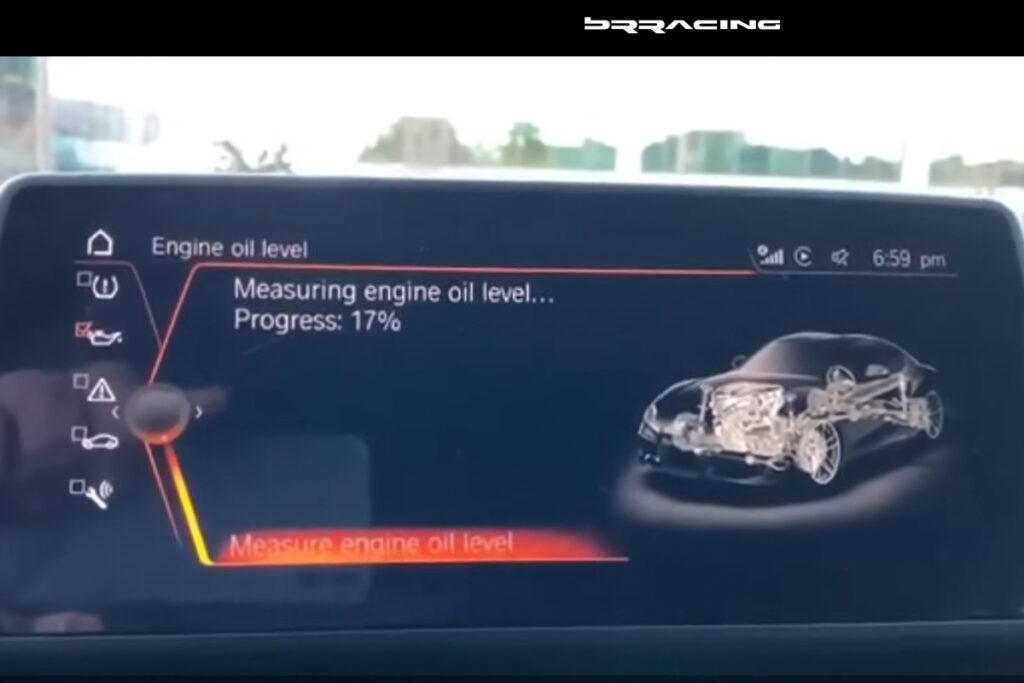

It starts out so innocently, no big deal, no fan fare. It starts by not letting you get an oil level reading. You ask to check the oil level, and it never gives you an answer. Somewhere, around the same time, you get an oil pressure warning light. What’s UP?

The issue surrounds the BMW B58, probably one of the best engines that BMW has ever made. The B58 engine first appeared in 2015, and is now in it’s 3rd generation. The magnificent S58 engine (used in the BMW M2, M3, and M4) is also based off the B58. The B58 was the successor to the BMW N55 engine…but, it was not an evolution of that motor, it was a completely new iteration.

The B58 is part of BMW’s modular engine family, each engine using a displacement of 500 cc (30.5 cu in) per cylinder, following the B38 and B48 engine. The B58 engine was named to Ward’s World’s 10 Best Engines four times, in 2016 (installed in the BMW 340i), 2017 (BMW M240i), 2019 (BMW X5) and 2020 (BMW M340i).

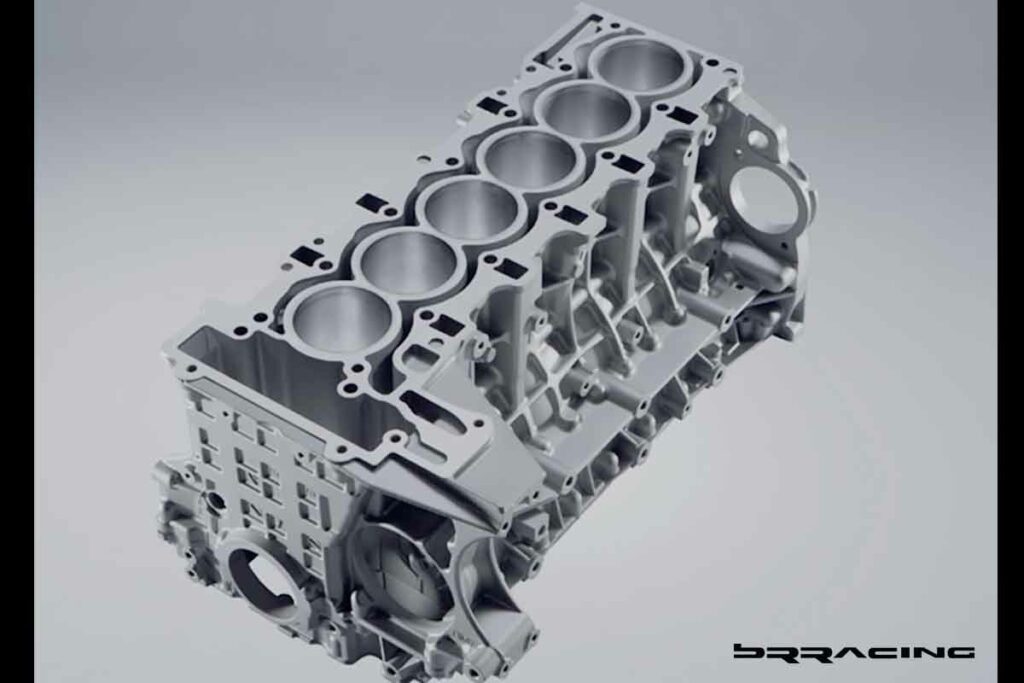

Compared with its BMW N55 predecessor, the B58 features a 20% increase in boost pressure, a closed-deck engine block design,….

versus the weaker, “open” deck design of the prior N55 block (the open being the open areas around each cylinder, versus the solid area around each cylinder of the newer B58 seen above (see below the design of the N55)

The new B58 has an increase in compression ratio to 11.0:1 and a slight increase in displacement from 2,979 to 2,998 cc (181.8 to 182.9 cu in) with added weight of only 8 kg (18 lb).

The turbocharger is a twin-scroll design, for more efficient power delivery with less turbo lag and more power than a conventional single turbocharger, as well as for weight and space saving benefits. The intercooler – a water-to-air design – is integrated into the intake manifold, to reduce the loss of boost between the turbocharger and the cylinders and the distance the compressed output turbo air has to travel to get to the cylinders.

The B58, like its predecessor the N55, features direct fuel injection, variable valve timing (called double VANOS by BMW), and variable valve lift (called Valvetronic by BMW). The B58 also features an engine-mounted heat encapsulation system to reduce engine wear and emissions during start-up. For durability and longevity, the rotating assembly has a forged steel crankshaft and forged connecting rods. (Very unusual in a large, mass production engine, normally only found in race motors).

As a part of BMW’s modular engine family, the crankcase is a completely new design identical to the B57 diesel version, engineered as both a gasoline and diesel engine in one common part. The closed deck crankcase is equipped with a completely new structure which can be identified by a complex array of ribs on the exhaust and intake side and an additional reinforcement frame on the oil pump side.

The engine was revised in 2018, dubbed “B58TU”, with notable changes and improvements. The fuel system was updated with 75% increased pressure with updated high pressure fuel pump and injectors, a new particulate filter in the catalytic converter, a new one-part timing chain as opposed to the earlier two-part, and new separate cooling circuits for the cylinder head and crankcase. It also eliminated the problematic front timing chain crank hub, with a new one piece design. For weight savings, the crankcase wall thickness and forged crankshaft were optimized, and the exhaust manifold was integrated into the cylinder head housing.

Another engine revision in 2022 (Gen 3) added port fuel injection to complement the existing direct injection system for better emissions and functionality.

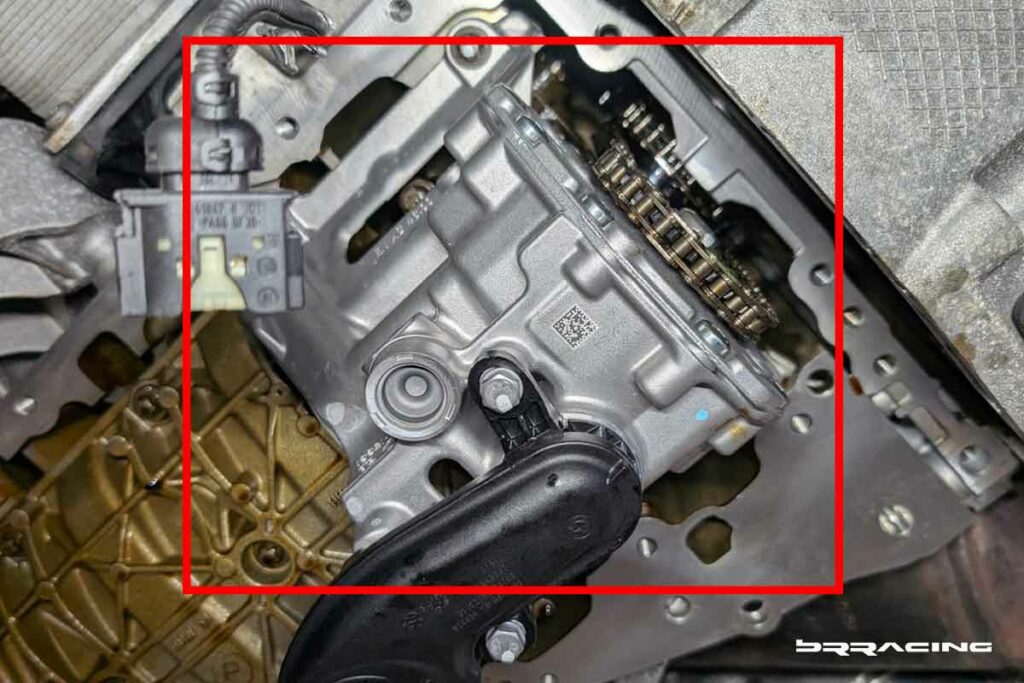

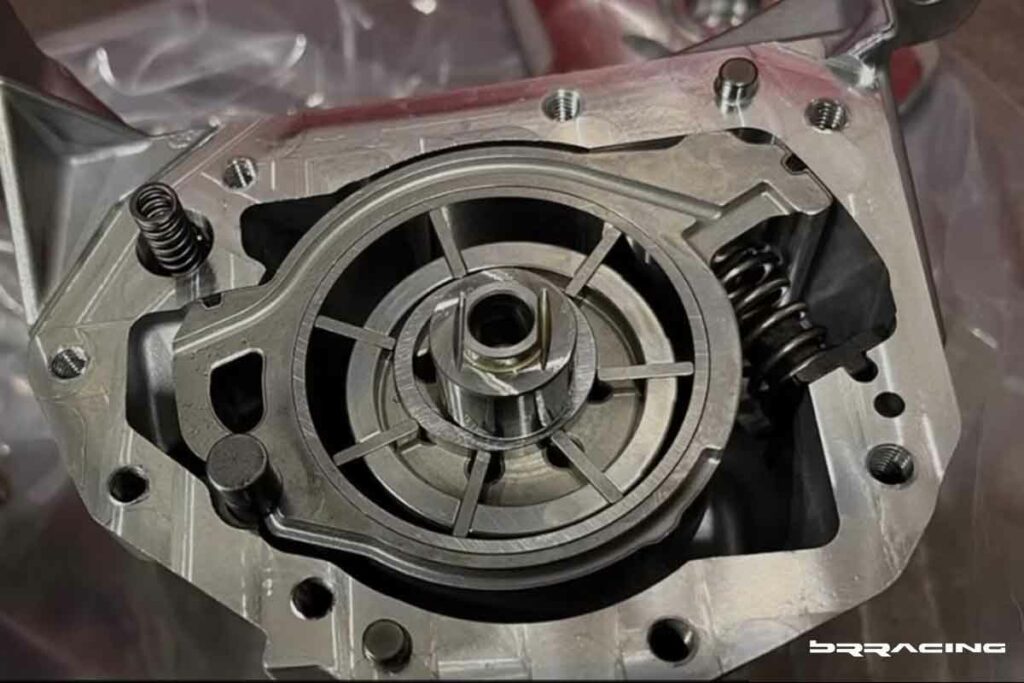

So, what’s the issue? All engines continue their technological innovation, and another one was the integration of the engine vacuum pump and the oil pump into one unit. See the image of the oil pump below.

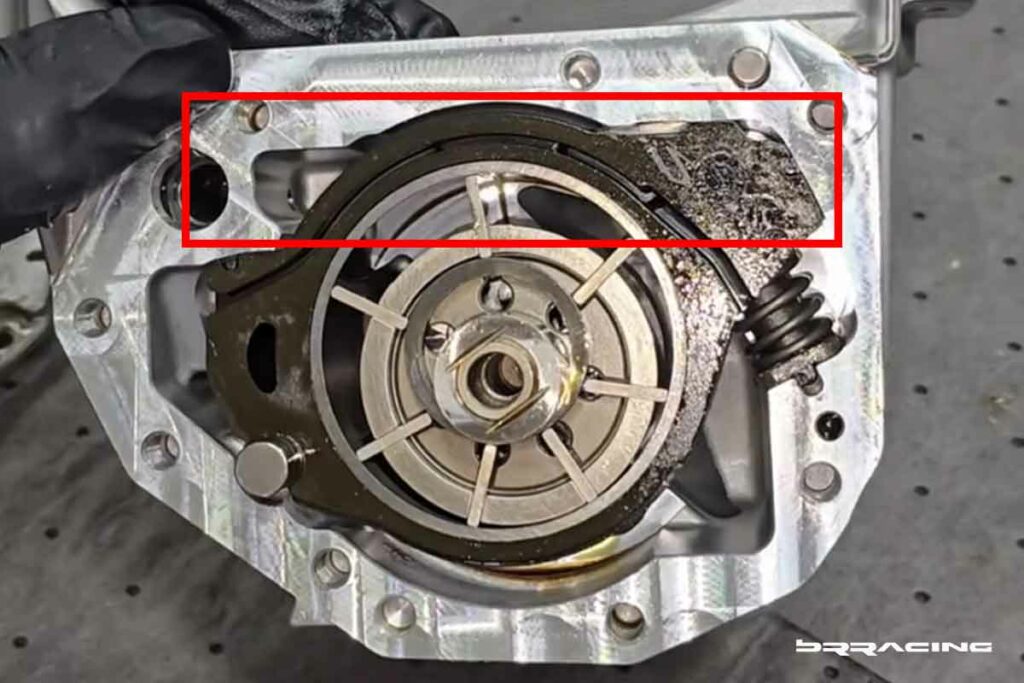

This a variable output oil pressure unit, so that it matches the engine need with the oil pressure required. This is the start of the issue. There is also another change that is affecting the oil pump…that is the oil that is being used. So, again, what’s the issue? The issue is that the oil pump breaks internally, preventing the proper level of oil pressure, and your motor could die. What breaks? The inside of the oil pump, which has a variable pressure design, has a plastic outer ring. This ring, cracks, and causes the variable pressure design to break down, or the oil pressure doesn’t change as needed, and it starves the engine of oil.

What causes the plastic ring to crack? This is also where it gets interesting….most failures have been found or caused in engines that have seen extreme cold (read, below ZERO F environments, AND, in engines where the car has been running the wrong viscosity oil. The specified oil viscosity for this engine is 0w20. Many are leery of this low viscosity oil, and have run 5w30, or 5w40, or even 10w60.

BMW recognized this issue, and later changed the design of the internals of the oil pump, replacing the internal plastic ring with a metal unit. This first appeared in 2022 engines.

The issue affects B58 engines from 2018 thru 2022. The Gen 1 version of the engine does not seem to have these failures, and the newer engines (since 2022), w the upgraded oil pump, also do not seem to have these failures. So, if you have a BMW powered by a B58 engine made from 2018 to 2022, then you may be exposed. If you have an engine in that range, then you can do the upgrade, but it’s not a quick fix, as replaces the oil pump is not a simple matter (engine has to be supported from above, subframe has to be dropped, then the oil pan and internal splash pan, then access to the oil pump is possible.

Be aware, and if you have an effected engine, look for the warning signs, and make sure the right oil viscosity is used.

BRracing – helping you manage your car for reliability