Every now and then, we get the opportunity to build a project car for a customer, and they want the ultimate solution….they want to go “All IN”. Such is the case with this BMW M2 Competition. The base M2 has become the recent BMW model to own, the true drivers car. The BMW M2 Competition takes the M2 to the next level, and for many, as the name implies, for track use. But while the M2 Competition is a great platform, there are always compromises….we intend to eliminate those compromises.

The M2 Competition has several major improvements over the base M2:

- S55 engine (true M sport version)

- Twin turbos versus the M2 single turbo

- Upgraded engine cooling due to increase HP

- 40+HP increase over the base M2

- M Sport Brakes (Front = 6 piston, 400mm” floating rotors, Rear = 4 piston, 380mm floating rotors)

- M Competition Wheels (19″)

- Upgraded Interior

- New Front Bumper, Increased Cooling, Ducts

- M Active Differential (electronic active multi-disc)

Not a bad platform at all…as mentioned, one of the best BMWs they have made in years. But, we want more…more everything. More power, more grip, more handling, better exhaust sound. We want it all.

ENGINE

We want Porsche GT3 beating power…but, to get there, since the car weighs over 3500#, that means we need over 600HP. Not a problem, just several pieces need to be addressed to provide reliable, smooth, linear power.

- Upgraded Turbos and Engine Software Upgrade (tune)

- Upgraded Intercooler

- Upgraded Radiators

- Upgraded Crank Hub Solution

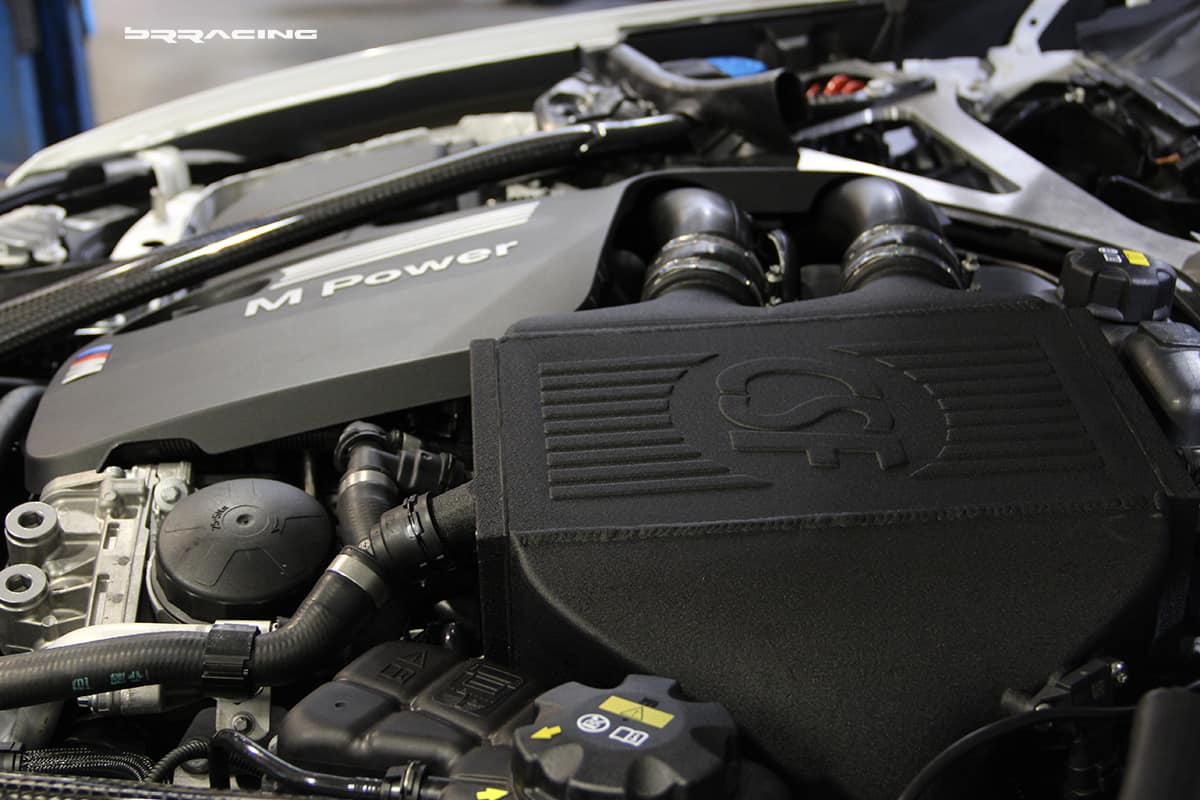

Here is a view of the BMW M2 Competition engine compartment before we start our upgrades:

Turbos, Software

And now, the upgrades start:

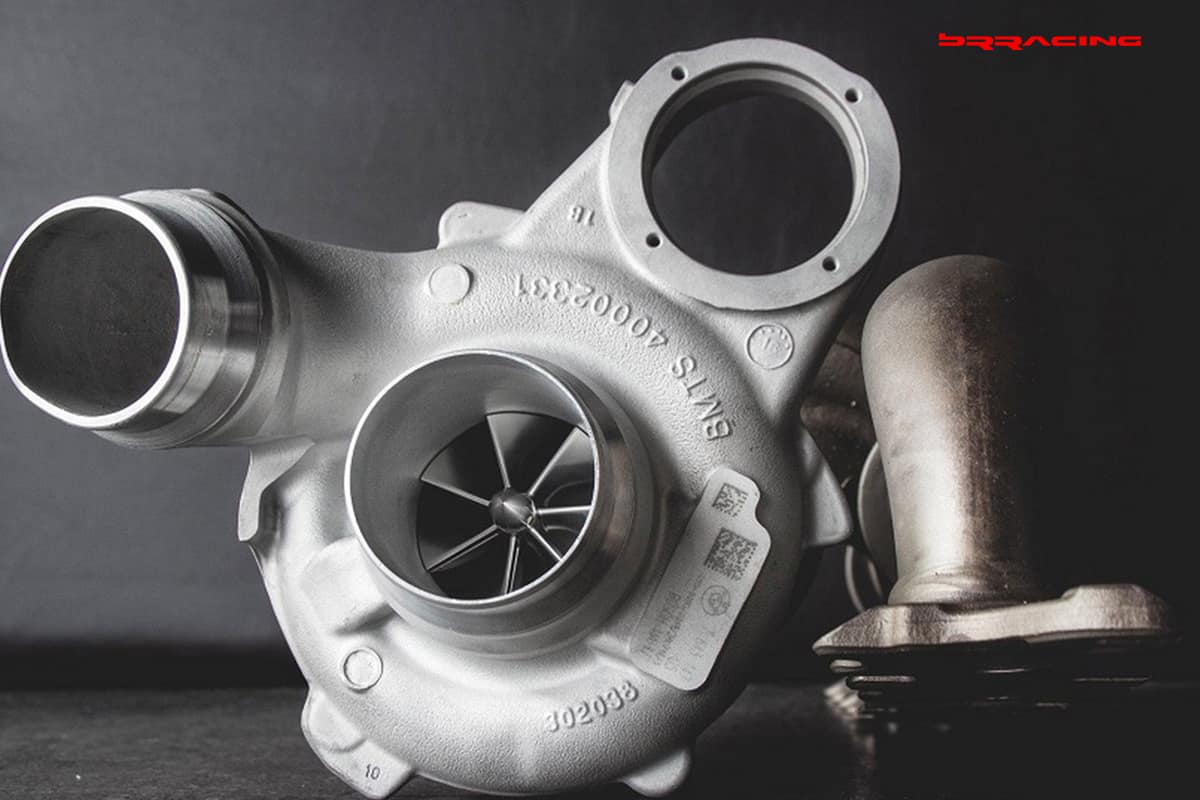

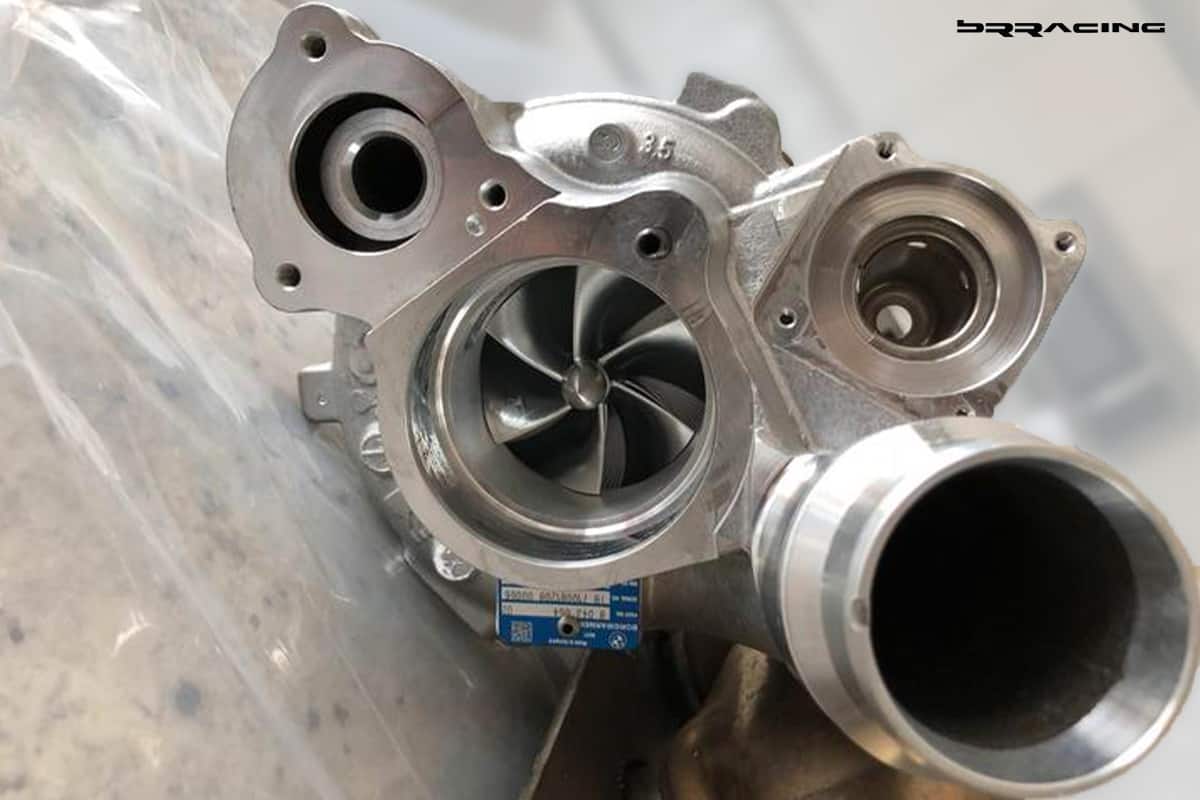

Almost all internal combustion engine (ICE) these days are turbocharged. They make for great solutions, but often come with slight tradeoffs. If you want big horsepower, you traditionally get low RPM turbo lag. If you want quick, initial throttle response, they you run out of steam at the higher RPMs. When BMW converted the S55 engine for the M2 Competition, they slightly “de-tuned” the engine, but we know what the S55 engine can do. Packaging in the engine bay is tight, so the traditional approach is to go with bigger turbos, but using the stock turbo housing. That was the approach we elected to employ here…PURE Turbos. Ported, polished, larger compressor and turbine wheels, balanced, port matched (exhaust manifold outlet port to turbo inlet port). Results…more power, across the RPM band, linear throttle response. This, combined with the upgraded software “tune” to manage fuel ratio, engine camshaft timing, total boost, and engine cooling, has put this engine well over the 600HP target.

Intercooler

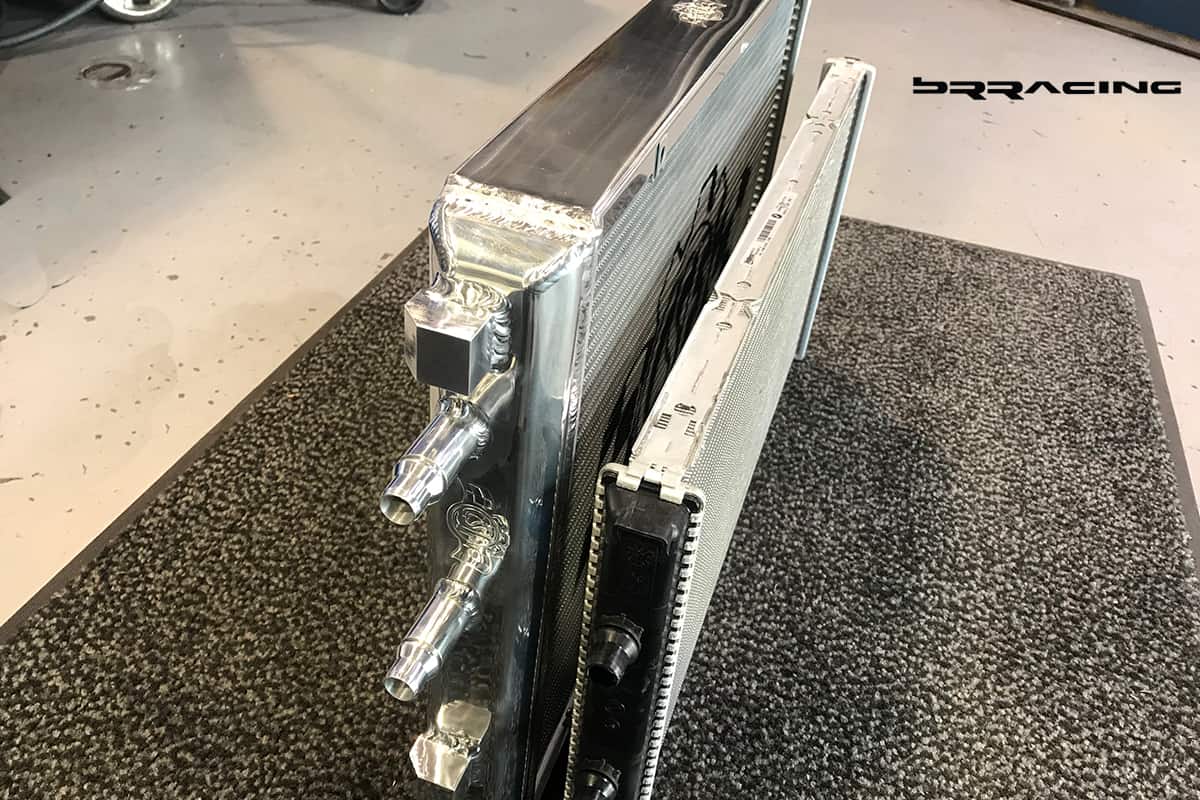

In implementing a solution such as this, you have to consider all elements of the engine upgrade. With more power, comes more heat. With turbo charged engines, if the heat transfers to the incoming intake “charge”, you lose some of the gain. The denser we can keep the incoming air flow, the more fuel that we can add…the more fuel, the more power. The BMW S55 uses a two stage “air to water” intercooler situated on the top of the engine. Good location for proper air flow, but limited then in terms of the cooling efficiency. We choose the CSF upgraded “air to water” intercooler. 60% larger capacity, better heat distribution, dual core, cross flow, fully cast solution.

Radiator / Heat Exchanger

More power means more heat. More heat means both from the turbos to the incoming air charge (but to keep that incoming air charge cooler, the intercooler is used, but the intercooler is an “air to water”, with the water acting as the cooling agent, so we need to improve the cooling of the intercoolar coolant / water, thereby increasing its effectiveness), as well as more heat from the engine itself. To keep the engine temperatures under control, two elements need to be upgraded. The front mount radiator / heat exchanger, and the speed of the water pump (more flow, more cooling – done via the software tune). The BMW M2 Comp has cooler everywhere on the front of the car…right front fender liner, left front fender liner, main center section, underneath the main center section for the DCT cooler.

We have used both CSF and Mishimoto radiators / heat exchangers in the past, but have had better reliability with the CSF versions. Unlike the stock BMW radiator (part plastic, part aluminum), the CSF versions are 100% aluminum, improving strength, reliability, and not really increasing weight. With track activity planned, the CSF heat exchanger also offers a grill / shield, to protect it from incoming objects (like rocks, tire debris).

Crank Hub Solution

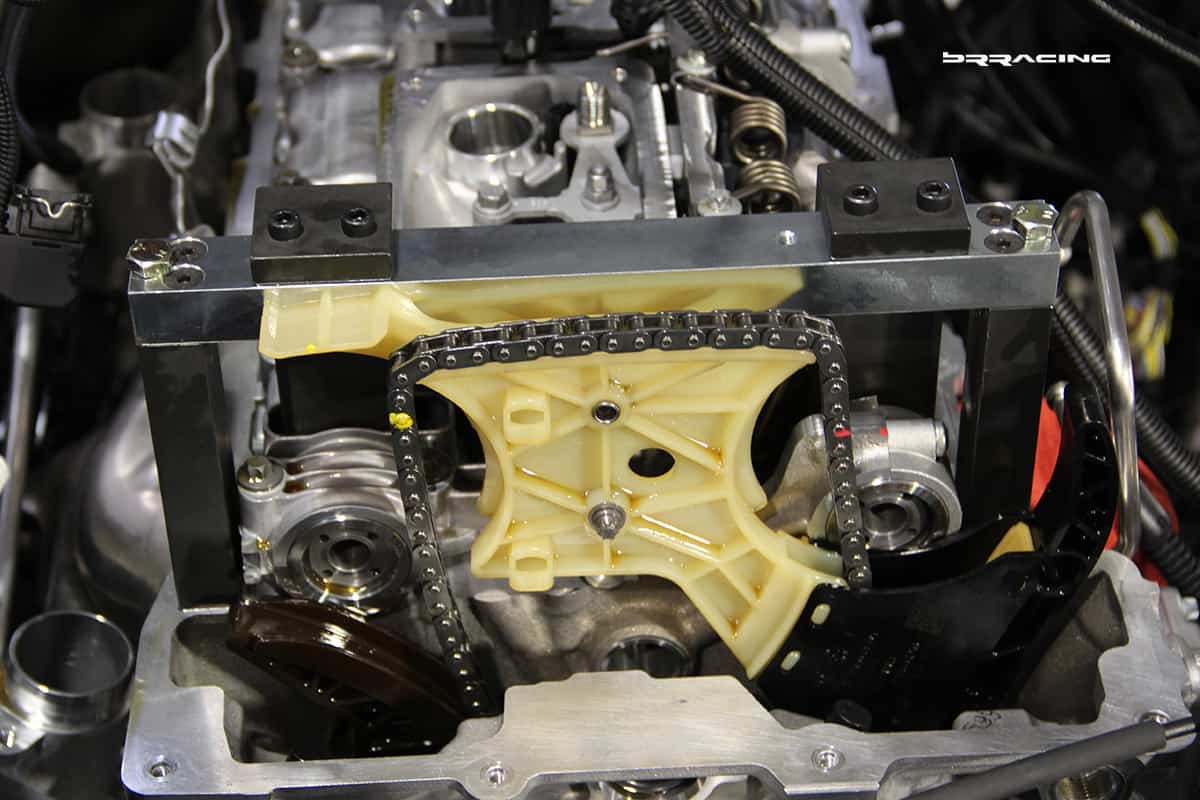

In the old days, the front timing chain gear was installed on the nose of the crankshaft, and kept in place by a “key way”. Time proven, known solution. However, the “key way” approach is not too manufacturing friendly. With almost all engines being assembled by robots, and time being very valuable, anything the manufacturer can do to simplify (for automation of assembly) the implementation, the more money / costs saved. We have seen several different approaches to this….Audi went from the “key way” to a wave shaped front crank nose and timing gear, to help self center the timing gear when been assembled. BMW choose an even easier approach, both the timing chain gear and the oil pump chain gear and simply just slid on, and secured at a very high torque with a single crank hub bolt (lets call this the friction approach). Works for BMW, has millions of miles to prove the solution, has been tested in racing as well. All is good and well until you start increasing the total power of the engine. The torque the engine can produce is often outside the normal engineering tolerances, and if so, you get crank hub timing chain gear slippage. What happens when the timing chain gear slips? The camshafts get out of sync…and if the slip is great enough, the valves will be open at the wrong time, and your engine goes “bang”.

We knew with our engine upgrades that we were going to have more than 600HP, and somewhere around the 550HP is the conceived notion of where the BMW friction approach can produce slippage, so we knew that we would have to implement some form of crank hub timing chain gear fix to ensure that the issue did not occur. Here is a comparison of the new crank hub timing chain gear vs the original BMW OEM crank hub timing chain gear (the new one is part of the hub itself, vs the BMW version the “toothed” timing chain gear slips on the crank hub stub).

There are several solutions on the market as to how to address this, but we choose the Vargas Turbo Technology splined crank hub and crank hub mounting solution approach. When the failures have occurred with upgraded HP and stock crank hub (and there have been many), one of the other interpretations as to the “why” is that the crank hub nut either lost torque or came loose. The Vargas solution also covers that issue with their crank hub nut mount. This is not a simple job….to implement this solution, the whole front of the engine needs to come off, the timing chain, guides, tensioner all come out. That creates the access to the crank hub gear. Once installed, and the timing chain assembly reinstalled, then a complete timing set needs to be performed.

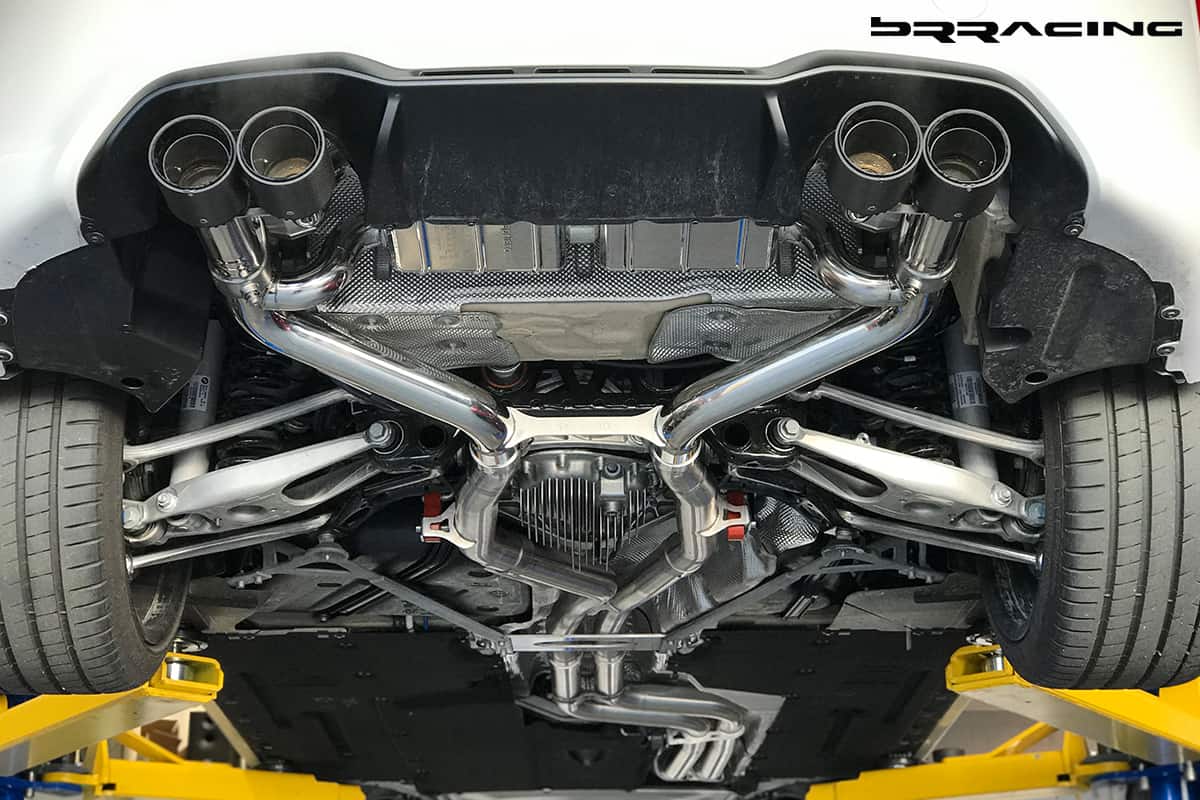

Exhaust

If we did not live in California, and were not under the California Air Resource Board smog restrictions, we would have implemented a complete exhaust solution that included either “catless” or “sport cat” type downpipes. But, since we are in California, and California does not allow the “cats” to be changed, altered, replaced in anyway, our exhaust solution would be a “cat back” type solution. There are many exhaust solutions out there, and we guide our customers to go listen to as many exhaust videos as they can, to determine which sound they like the most. Most exhausts that are “cat back” don’t do anything for performance….they may be lighter, better fitting, offer tip options, and sound better, so that’s what the decision should be based on.

Our customer elected to go with a “cat back” solution from Capristo. Great sound, great fitment, excellent quality. Not only maintains the “valvetronic” implementation, but also adds to that with a complete remote control of the valves.

Suspension

Coil-Overs

When reviewing the suspension needs / options, there is a simple decision tree that we follow. First is to understand the customers use case: street only, mostly street, some track / autocross, equal balance between street and track / autocross, mostly track / autocross, or all track. Next, what type of tire is the customer going to be using, targeting? Are there any ride height considerations? What is the budget? If track / autocross user, how aggressive of a driver is the customer?

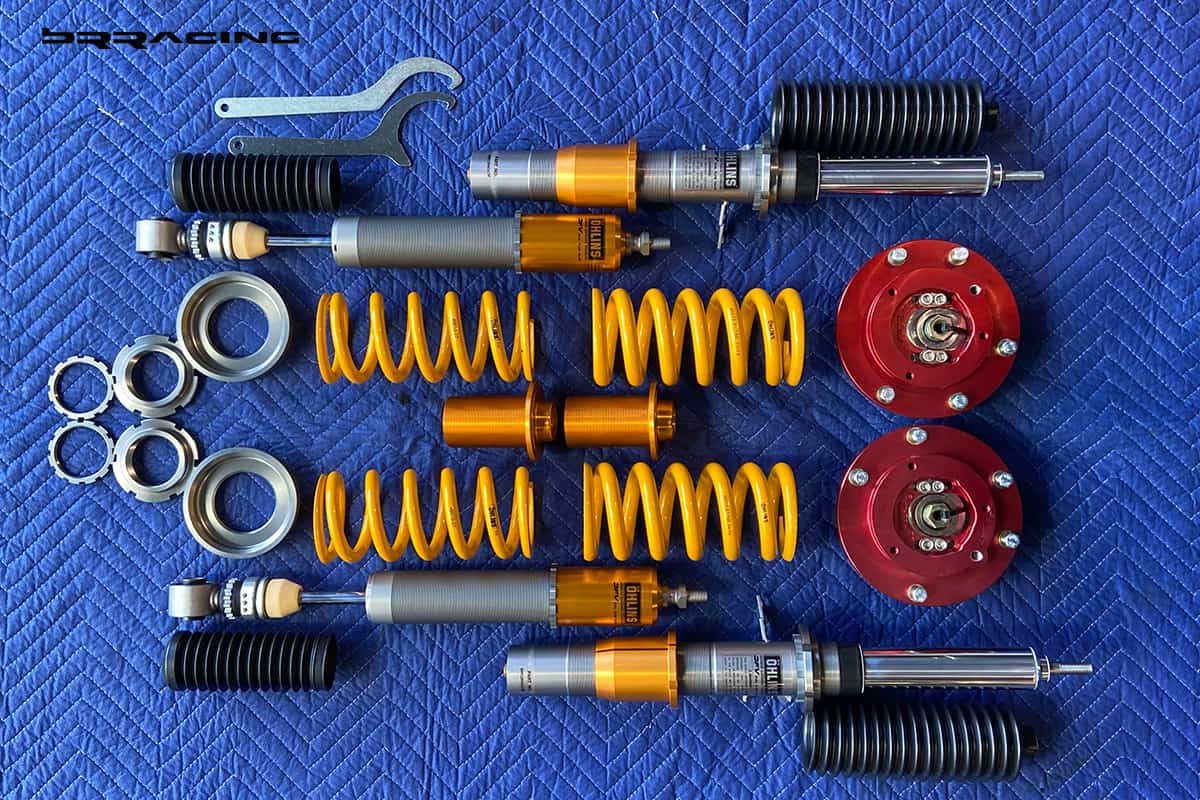

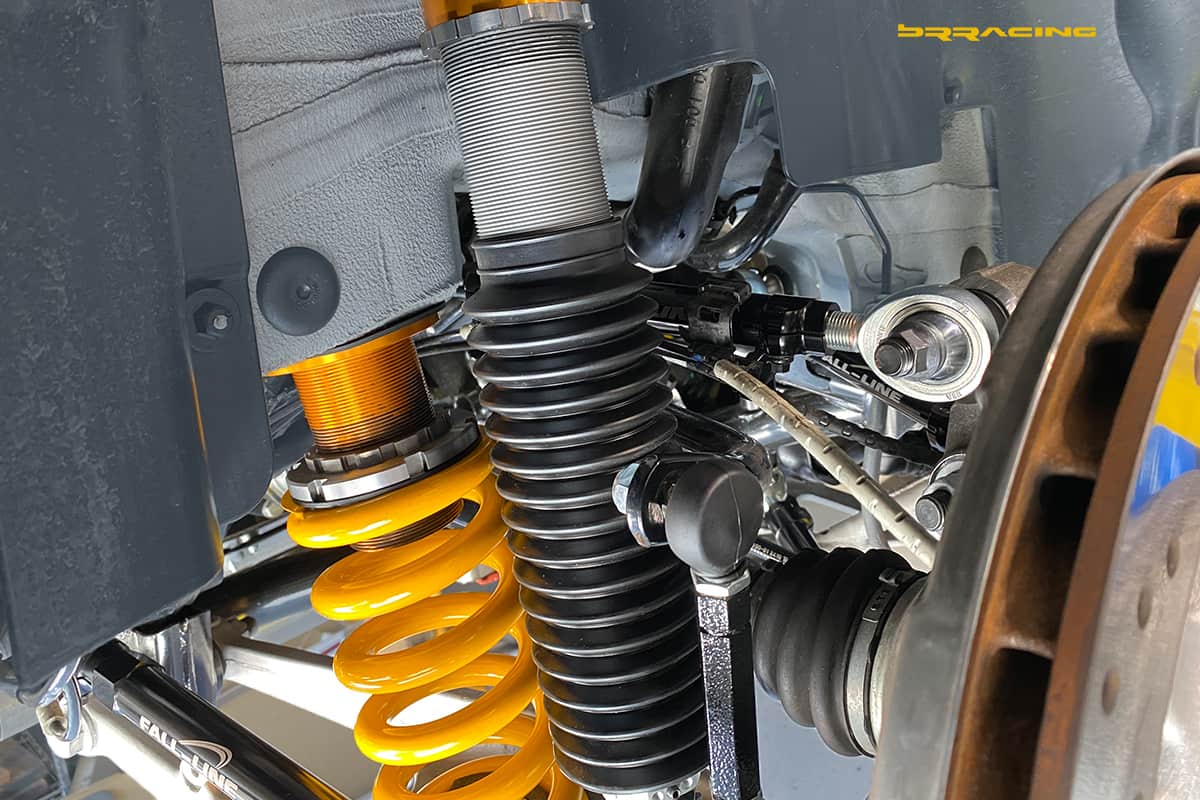

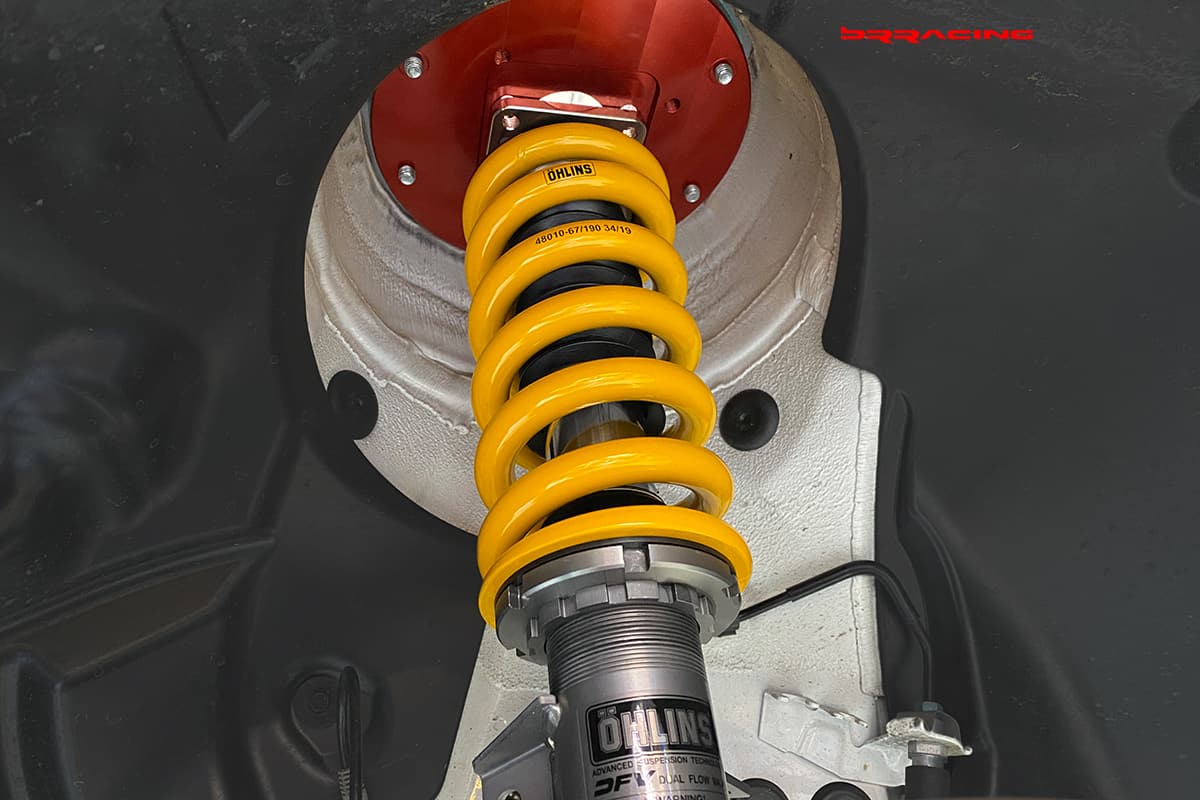

In this case, the car was to achieve aggressive track status…nuetral handling, lowered ride, adjustable suspension settings, nimble, precise. The BMW M2 Competition comes w mechanical type springs, shocks, struts, no EDC (Electronic Dampening Control). That set the objectives and therefore the decisions:

– Ohlins adjustable coil-overs

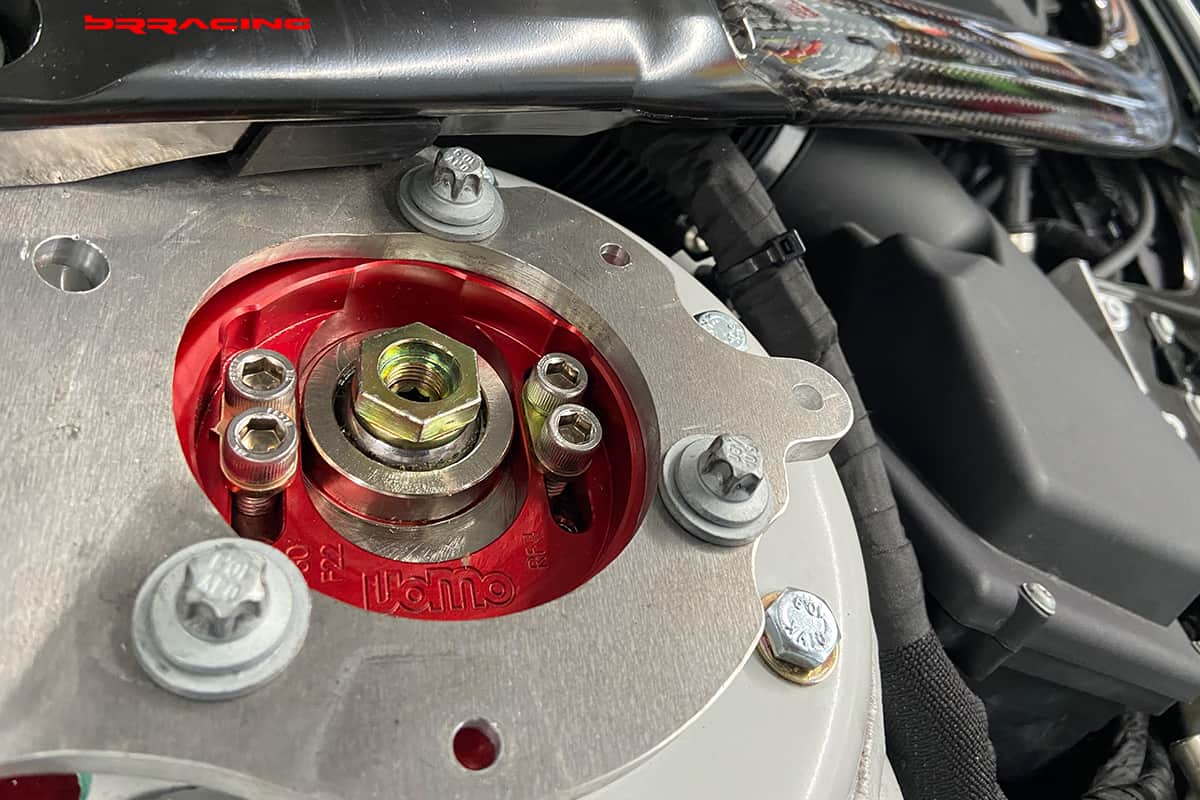

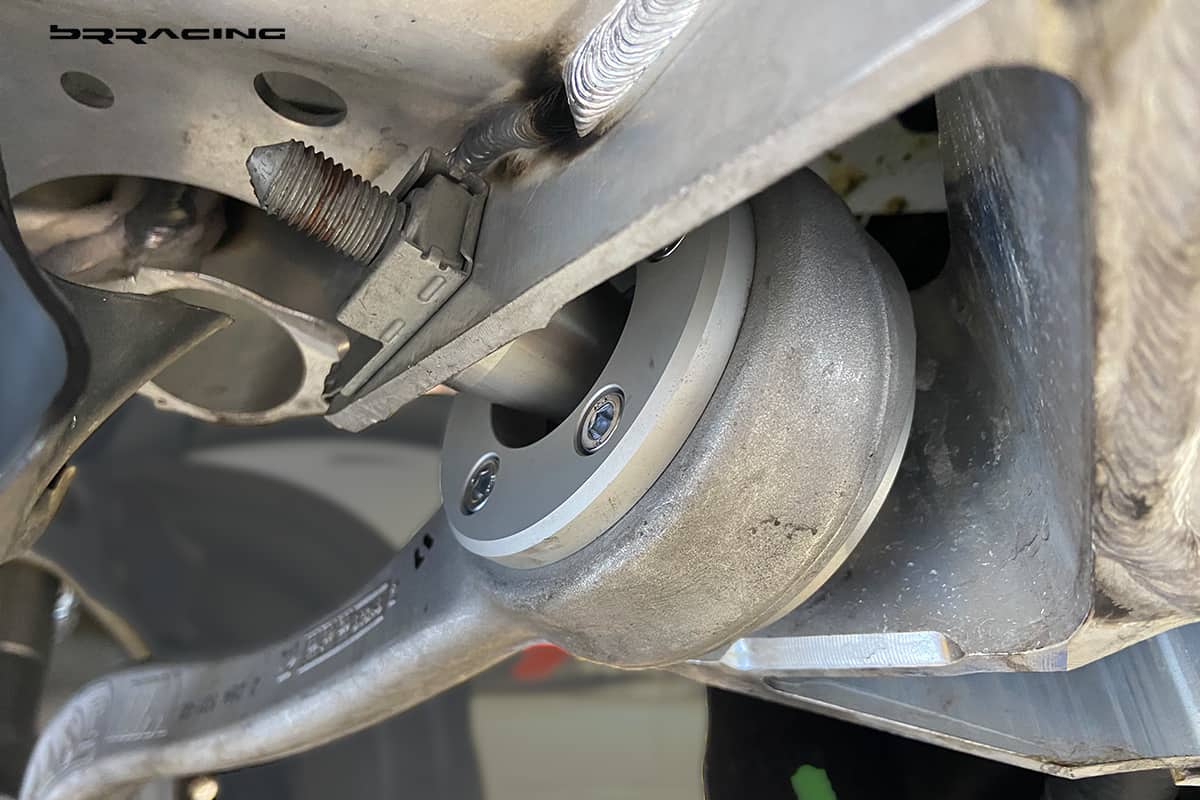

Adjustable Front Camber Plates

Not a lot needs to be said here….for BMWs, if you want the best adjustable camber plates, you select Vorschlag. Strongest, lowest “stack height”, easier to adjust.

Control Arms, Bushings

While the suspensions of the factory sports cars continue to get better and better, there is nothing that feels and drives as good as a near solid suspension. This is a critical decision….going solid is wonderful, but going solid is not meant for cars that are going to see a large percentage of daily driving or commuting. When people first drive a true race car, their first reaction is not about the acceleration, or the braking, or the noise, or the shifting, it’s the level of preciseness, and how the car just goes where they want it to go. A lot of this has to do with the elimination of the rubber bushings in the suspension, sub-frames, mounts. The more solid we can make the car, or the more we can eliminate the rubber, the more nimble and precise the car becomes. There are other benefits of going this direction…if chosen right, the suspension elements will provide for a much larger range of adjustment when it comes time to do the alignment, and will allow the right type of alignment to be achieved (we can not get there with stock type suspension adjustments).

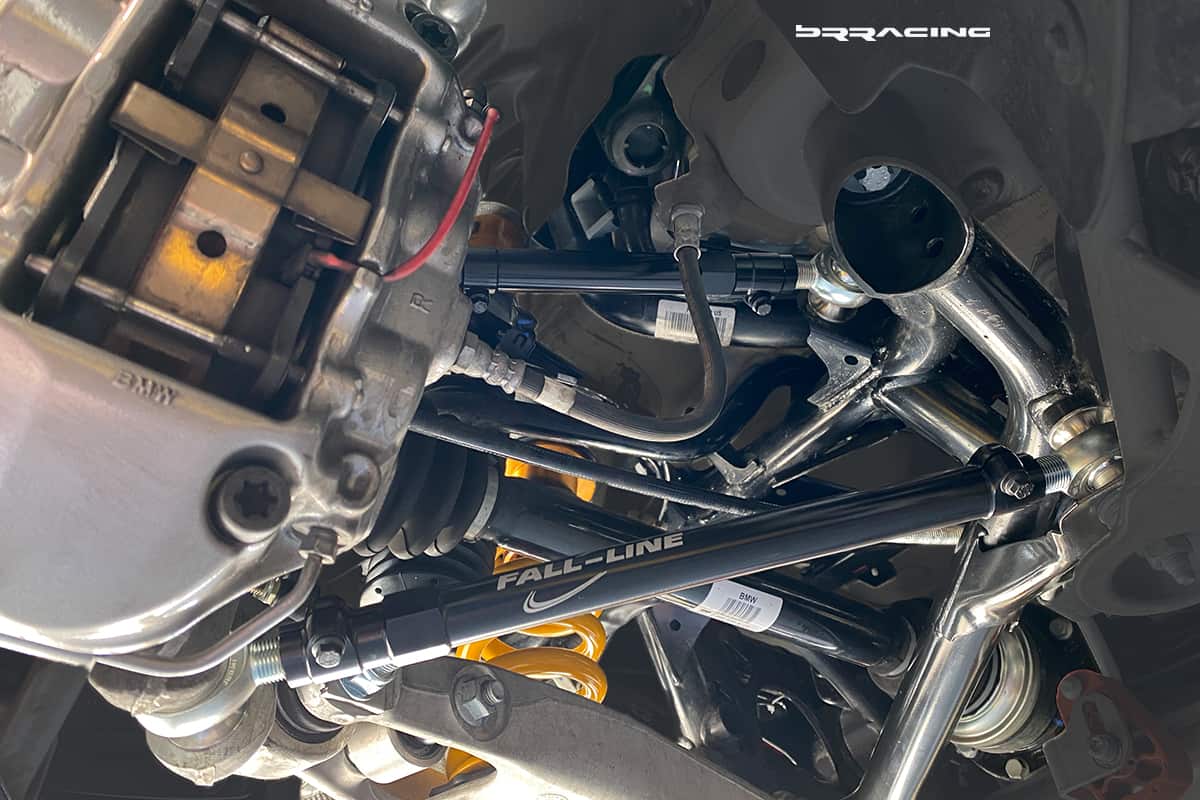

The objective here was to be the best….so, the best control arms / suspension bushings are from JP Novelli, also known as Fall Line. Not as well known as some other brands, but absolutely the best there is. Stronger, better built, pinch style adjustments, larger monoballs….factory race level suspension pieces.

Alignment

We continued to be amazed at how little most tire shops and independent service centers know about alignments, dealers even more so. The alignment settings to be chosen and implemented have to align with all the other factors already reviewed. Even on the forums, you will see all sorts of implementations of alignment, but rarely backed up with data to support the result. The combination of our very large Motorsports program, combined with our thousands of street alignments, has allowed us to develop a well defined structure to determine what alignment specs are best suited to each customers car, tires, use. This car was no different, a BRracing custom alignment was implemented.

Wheels

With the objective to have this be one of the best handling, performing BMW M2 Competitions there is, then the decision was made that we needed to optimize the wheel and tires. For wheels….we needed light, strong, and optimized fitment to allow for the biggest tires we could fit inside the stock wheel wells. Given those requirements, the decision was quite easy….a full set of HRE R101 forged wheels. For tires, we were going with Michelin Pilot Sport Cup 2 to start.

Finished Product

The car is just amazing in every way. Streetable, quick, brutal acceleration, great braking (the BMW M2 Comp comes w massive BMW M5 brakes to start), precise and predictable handling, intoxicating sound. Looks great, goes great, sounds great.