We often talk to our customers that there are three types of cars when it comes to upgrades, there are (1) street cars that can be driven on the track, (2) there are track cars that can be driven on the street, and (3) there are race cars. When customers become committed to the upgrade path, and wanting to evolve their car for track use, then understanding what the long term objective is, and what decisions are rational and good financial decisions is key. If the objective is to get to a race car, then bypass the whole upgrade path, and just buy a racecar (new or used). In this case, the objective was clear…to make this 991.2 Carrera the fastest track car possible…but not going over the line of making it a race car. The other underlying objective was could it be made into a better track car than a same “gen” GT3? The platform offers that, but can we get there (since the base Carrera is a turbo based engined car, the ultimate HP available can be more than a GT3…so, can the rest of the platform also be made better? That was the plan.

ENGINE

So, since we mentioned that the engine offers a great platform, foundation, to generate more HP and Torque than a GT3, what steps did we take? We don’t want to go wild, as we have done that w other Porsche turbo cars, but if you get carried away w the HP focus, you can get there, but most of the power becomes wasted….as once you get above 600HP, most street cars can’t get the power down effectively. Therefore, we wanted to add power, but we also wanted to improve low end torque (for power coming out of the corners).

There may be more that we do…but we are taking it a step at a time (see our other blog article on the Porsche 991.2 Carrera T for all the power upgrades that can be implemented, thinks like intercooler, turbos, headers, intake plenum, throttle body, intake manifold). See here:

https://www.brrperformance.com/%ef%bb%bfporsche-991-2-911-carrera-targa-more-power/

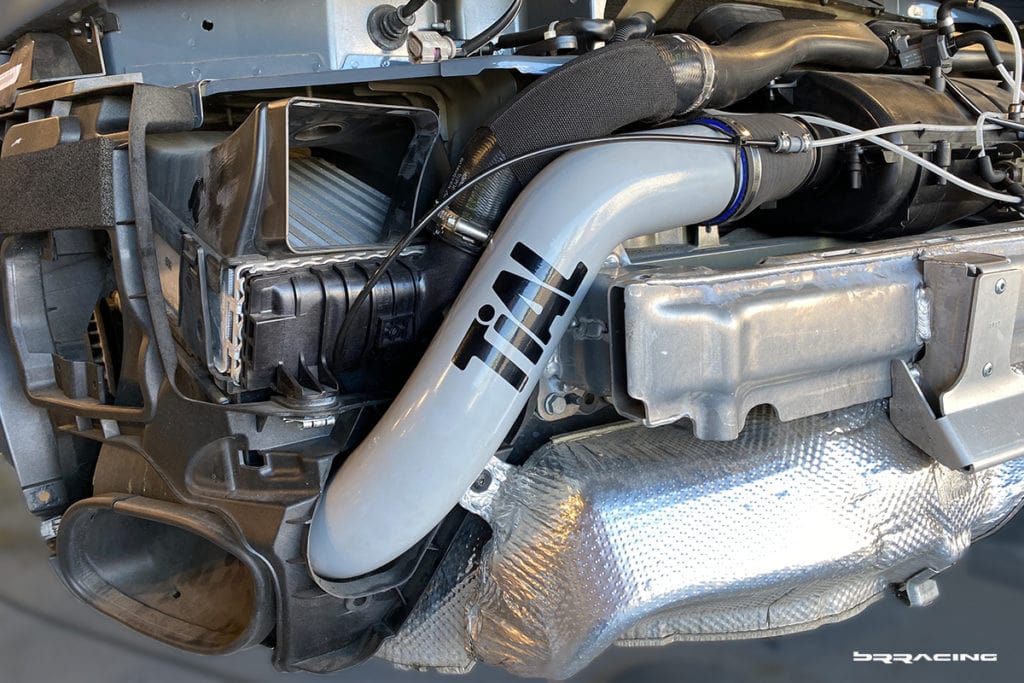

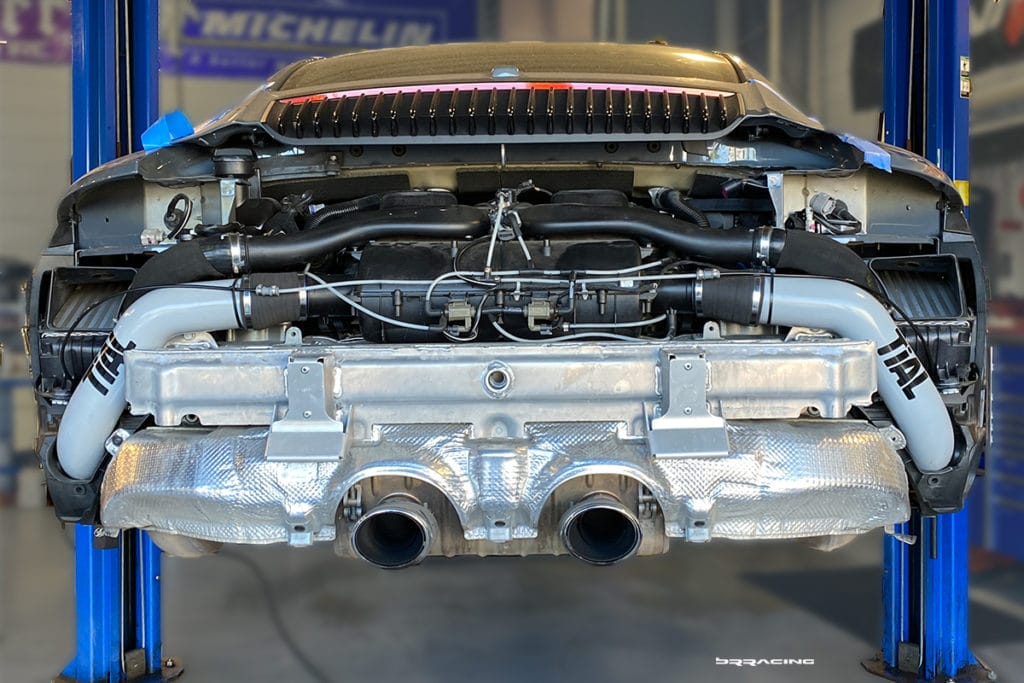

To help the engine respond better, we needed to feed the turbos more air. So, in with the upgraded TiAL lightweight inlet tubes 3D printed aluminum inlet tubes, you can’t believe both the how clean the internals are, and how light they are.

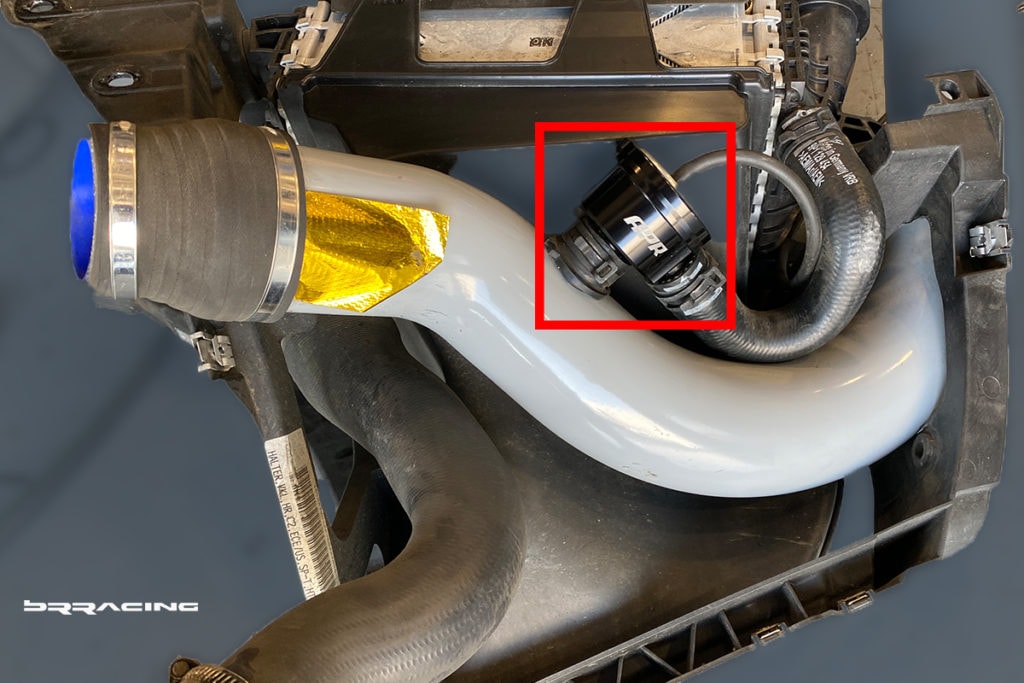

As mentioned, we wanted more air to the turbos to get them to spool faster. But, there is another side to that as well. Once the turbos have spooled up and are fully on boost, when you come off throttle, like entering a corner, you also want the turbos to be “on boost” when you start to apply throttle as you prepare to exit the corner. So, upgrading the divertor valve, which allows the level of boost in the intake system to be higher…therefore, less time to spool up again as the throttle is opened (however, be careful here, just like adding bigger turbos, if too much boost is added, it is likely the rest of the intake system will need to be addressed, especially since most of the parts are made of plastic, and if boost is too high, they will go “boom”.

EXHAUST

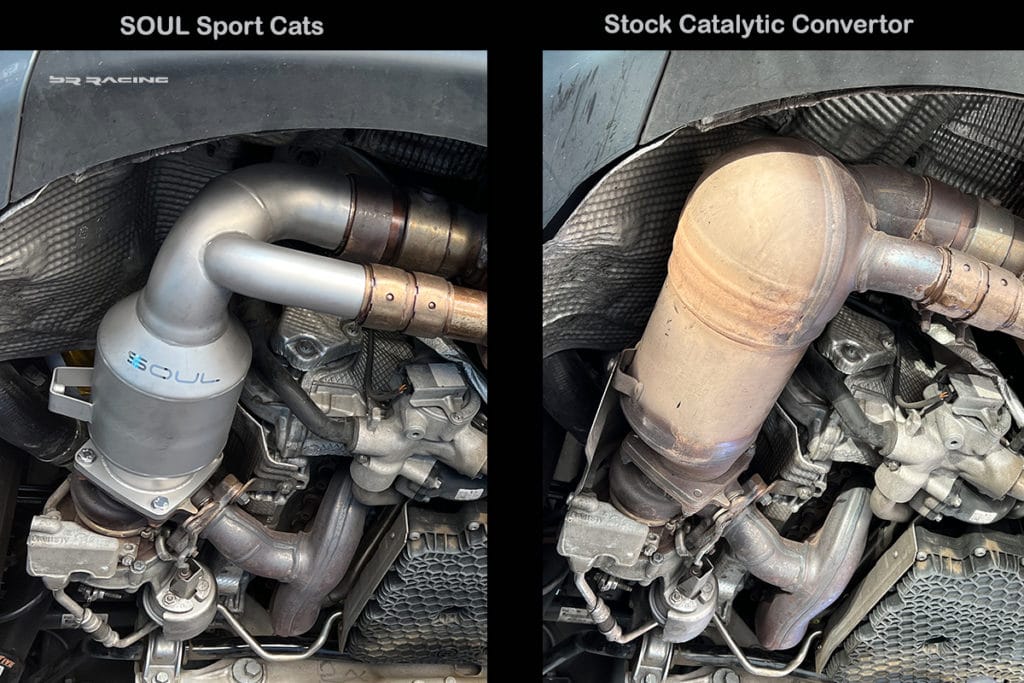

If we are trying to help the turbos, we need to do some upgrades on the exhaust side as well to let the exhaust from the turbo exit faster, or have less back pressure under higher levels of boost. Unfortuneately, we can’t get carried away here, as our customers drive in California, and most California tracks have sound limits (we have some Porsche 991.x Turbo, and Turbo S customers that drive in events like the flying half mile, or full mile, and they have no sound limits, so we can run full straight pipes for the exhaust, and make as much noise as we like (and unlike track use, for “flying miles”, we just need to let the turbos run wild, so no back pressure is a good thing)). So, given the parameters we have to play within, we wanted to address the most restrictive element in the exhaust, which was the catalytic convertors. We selected SOUL Performance for the exhaust solution (great fitment, amazing quality, super customer support, great look, high flow).

DRIVETRAIN

So, now we have more power, better throttle response. How do we get that power to the ground?

In the Porsche 911 hierarchy, each model has a slightly different set of features….each a little better and more significant as you move up the chain, till you get to the GT3 or GT3RS. Another way to look at it, as you step down from the GT3, each car is missing key things. Things like brakes are different, drivetrain is different, engine is different, aero / downforce is different. Well, one of the big holes in the Carrera, Carrera S, Carrera T, is the drivetrain, specifically the differential. In the GT3, you have a full, mechanical, limited slip differential. In the Carrera, Carrera S, Carrera T, you get NOTHING. It is a plain, “open” differential. This is a huge limiting factor in trying to get power down when coming out of corner. In the Porsche world, there are also different sizes to the transmission and differential housing. So, you can’t just take a GT3 LSD and throw it in.

So, we look at all the options, versions, types, and selected the OS-Giken mechanical LSD. Just in case you contemplate doing this upgrade, be aware that the differential assembly has a set of bearings on both sides of the diff….even the open differentail assembly that will come out. However, you can NOT buy a set of bearings. They are not an orderable part. There is no part number on them. You still think, no big deal, bearings have been around forever…so you call the main bearing companies….and they reply they don’t have a bearing set in that size. So, there is high risk here….as you have to take the old bearings off the old diff, and transfer them to the new diff. But, the way the diff is made, you can’t get in behind the bearing set to pull them off. You also don’t want to stress the bearing, the bearing carrier or case, or bend it, as once damaged, you can’t buy another. In fact, you can’t buy the diff w bearings either. So, if you need another set of bearings, you have to buy A WHOLE TRANSMISSION.

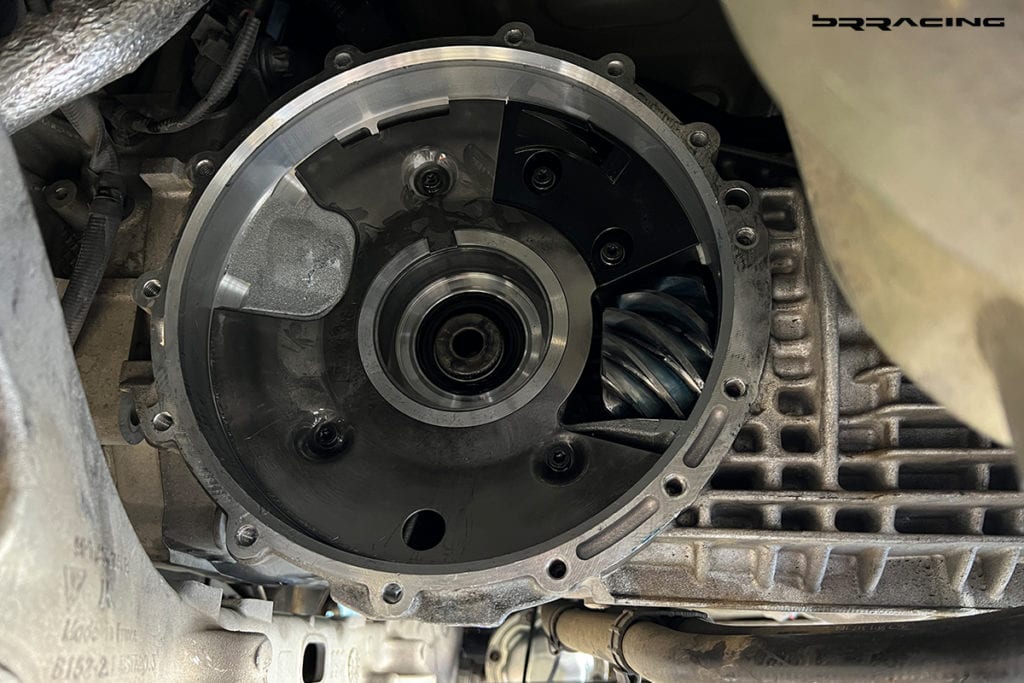

This first picture is the differential, w the side cover off, and the differential assembly removed. You can see the pinion / drive gear.

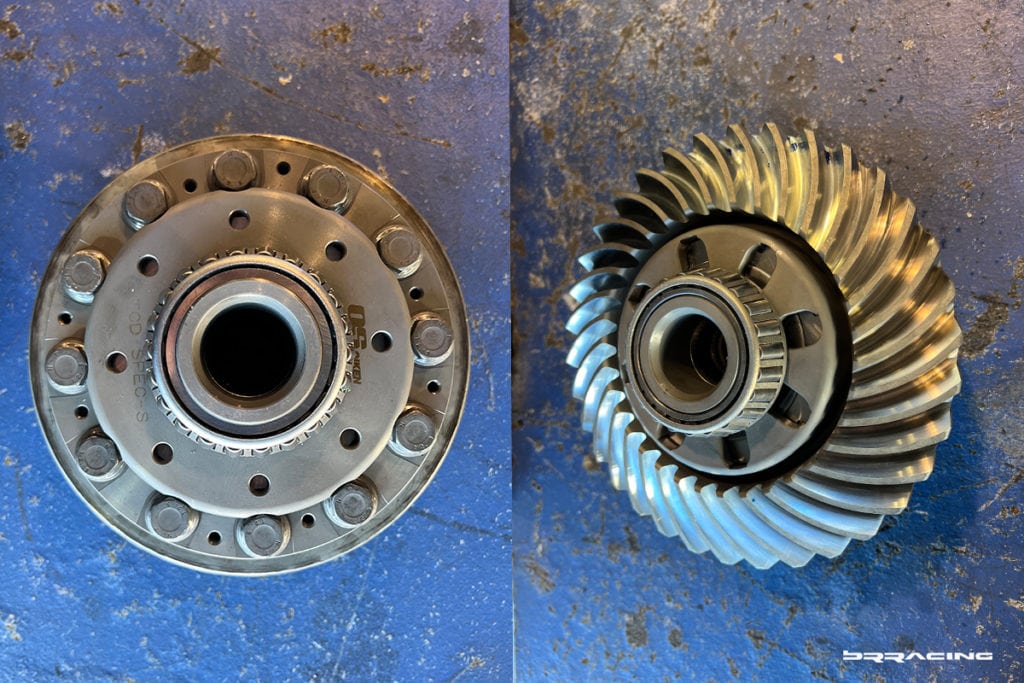

Another element is that not all differentials are the EXACT same size. It is important that the differential assembly be located exactly in line w the pinion drive gear. The ring gear will be removed from the existing differential and transferred to the new differential assembly. Once assembled, you now get to play the hard game of determining the centering of the differential ring and pinion. If the complete transmission is out of the car, then this is a lot easier to accomplish, as you can see into the rear of the differential, and adjust as needed. What does “adjust as needed” mean though? Since they don’t sell differentials, they don’t sell differential bearings, then just the same, no one sells or makes differential “shims”. So, to do this implementation, you have to make your own “shims”….this is not an easy task, and there are several critical variables that need to be well understood if you go to fabricate them yourself. We have been doing differentials for our whole time as a company (and done them for BMW, Audi, VW, LMP3 and more), so have some idea of what is needed here.

Here is the new OS-GIKEN LSD w the ring gear installed and side bearings transferred over.

There is a normal, natural progression or evolution that we guide our customers thru once they have decided that they want to upgrade their cars. It’s easy to get excited about the upgrades themselves, and want to do some of the sexier things first or early, but we need to make sure that key steps are not forgotten. One of the most important steps is safety….we would say that almost all customers want to downplay this step, and push it off for the future, but we have been doing this for a long time, and we have seen what happens when this step is not addressed. Many customers are just getting into the sport, and have not experienced or seen the bad things that do happen, or think they are somehow special, and it won’t happen to them. But, don’t ignore this.

SAFETY

In the scope of this topic, there are just two items that want to address (and this is just the element of safety being implemented on the car, we already assume that asssume someone has a full helmet, and that the helmet will have a HANS as well (and to implement a HANS, you need harnesses…and to have harnesses, for the most part you need a roll bar / harness bar). So, the first step is to add a full roll bar / harness bar. (Now, again, if you’re reading this and you think you don’t need a roll bar, think again. We have been in several complete roll overs, and I don’t care what car you have (and hopefully, even more so, it’s not a convertible), you need a roll bar. We were involved in one car roll over by a student, and we almost could not get out of the car due to how seriously crushed the roof and sides were…..as instructors, we won’t get in a car anymore unless we have a roll bar, harnesses, and we can wear our HANS).

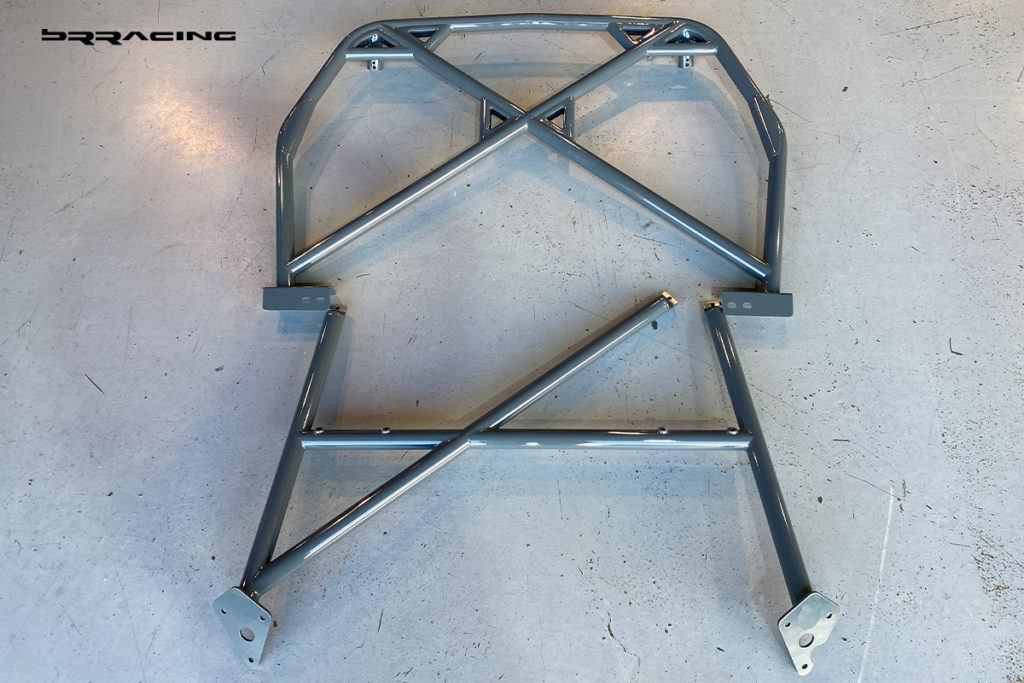

There are lots of roll bars out there, but in our view, there is only one choice. The GMG roll bar. It is the only one that has the added supports and reinforcements to ensure it does it’s job. Some people say they pick others as there is a slight improvement in rear visibility….screw that, we’re talking about your life. If the main roll bar collapses due to a poor design, your done.

This is the GMG WEC bar. You can see the “gussets” added at the main hoop bend, and the supports added at the other intersections…this makes a huge difference in the strength area. We had this bar painted to match the exterior color of the car.

There are a lot of choices in harnesses as well. The only specific here is this is a HANS compatible set, and the lap belts are a “pull up” style (you can have either pull up, or pull down on the lap belts….it is very hard for the driver to pull down on a lap belt unless they have crew that will do that for them). These are also Schroth Porsche specific versions, as how they can be installed is enhanced for the lap belts for Porsche cars, as there are key considerations on where and how the lap belts can be installed or attached, and there is essentially no room between the seat and the transmission tunnel. We also don’t want to drill holes in the car, as this is a street car, and it may be restored to stock orientation and sold later in its life. This car already has the Porsche Carbon Fiber single piece sport bucket seats (which allow for the support of harnesses)(Note – harnesses should never be used w seats that do not have the shoulder harness cut out holes).

So, what else can we do to help the driver? Not from a safety standpoint, but there are some other items we can do for the driver to help the driver experience. Like…the shifter.

SHIFTER

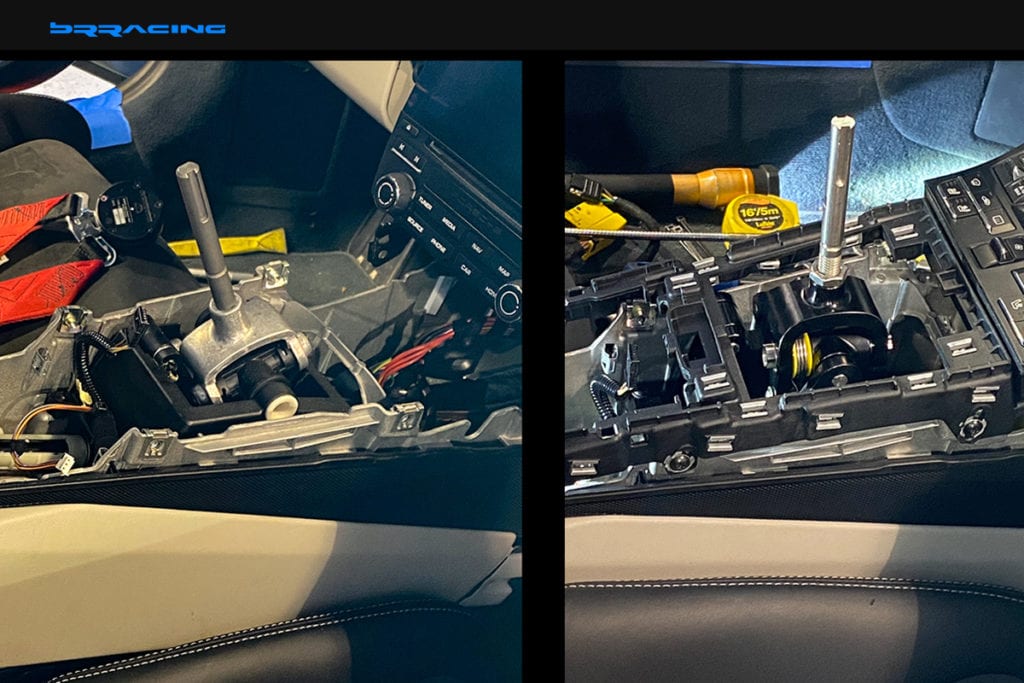

As a driver, you need the car to inspire confidence, to not take any brain cycles away from the focus on just driving. One of those things that can rob the driver of focus, is the shifter. The stock shifter is vague, and does not communicate well where exactly it is. We’re not so concerned with the “shortness” of the throw, but that is a nice piece to add as well. In the Porsche world, the best shifter / shifter assembly / shift cables out there are the Numeric solution.

There are two things that make the stock shifter “vague”. The shifter itself has rubber bushings that control the “fore-aft” and “side to side” directions. The position of those two directions determine the gear selection. The other part is the ends of the shift cables. The stock cables also have rubber bushings on each end. The Numeric solution replaces all the bushings w solid elements, is adjustable, and makes shifting very precise, direct. This removes shifting from being a full conscious effort to more of a sub-conscious effort, allowing the driver to focus on driving.

Now that we have a fast car, a safe car, we need to make it a stop. As mentioned before, the base Carrera is at the bottom of the food chain in Porsche’s option list, and has almost no brakes under stock configuration. The brakes on the base Carrera are the same as on some of the Caymans.

BRAKES

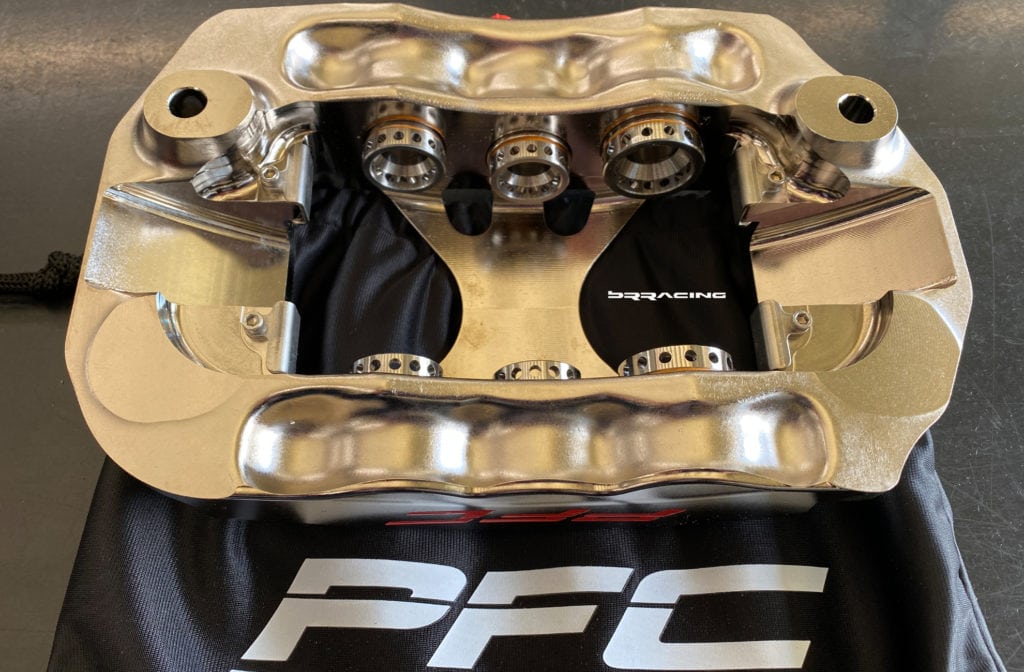

There are lots of options for brakes, but for the base Carrera, a minor upgrade is not going to cut it. We need real brakes, serious brakes, BIG brakes. There are the normal choices for big brake kits (BBK). Brembo, AP, Alcon. But, we wanted BIG brakes. The biggest kit we could find is the PFC Porsche Cup Car kit. Proven, known, tested. There is one important element that needs to be factored in when considering a BBK type upgrade….you need room inside the wheel to fit all that hardware. So, any brake decision is also a decision for wheels (at least you need to test in advance for clearance).

The PFC system is a full race type system. The calipers are fully optimized for track use. The caliper is sculptured, to shave weight, it is strength optimize to eliminate any flex, the caliper pistons are designed to not transfer heat from the brake pad / brake backing plate to the pistons, and therefore the brake fluid.

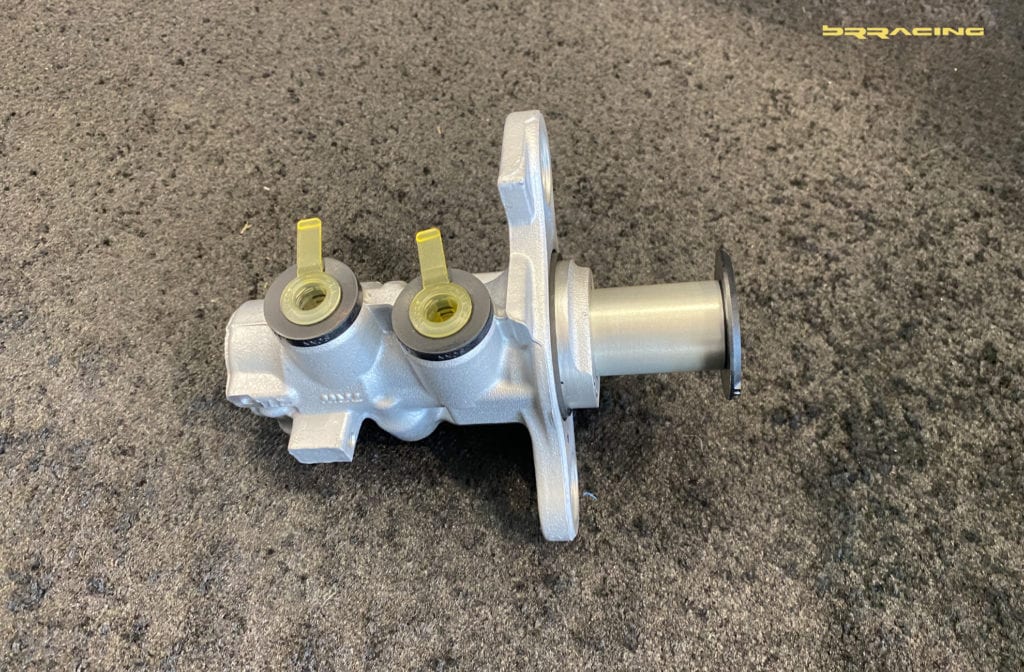

One of the pieces that people often don’t think through when doing a big brake upgrade, is the brake master cylinder. Is the master cylinder sized to push the right amount of fluid now needed by the pistons (either there is more pistons, or the pistons are now larger in size, which means more brake fluid volume needs to be pushed). This also has to do with the brake pedal feel. If the pedal has a long travel, and is vague, it is harder to develop muscle memory and feel.

Since the PFC kit was made for the Porsche 911 Cup Car, the natural change to the brake master cylinder is to implement the same there.

The result is a brake system that can take all the abuse anyone can dish out, will provide great stopping power ( which is directly linked to the size and type of tires on the car), but that also provides a very confident, consistent brake pedal to help train the driver in maximizing braking in all conditions.

As mentioned, we needed to consider the wheels when deciding on the best braking solution. So, if we are going to potentially upgrade the wheels, and we are going to be doing track duty, then we wanted to go big, and fit the biggest wheels / tires we could in the stock body. The best wheels out there…there is no question, are HRE. They make a specific light weight, forged wheel, optimized for track use (R101).

Now we have a car that will go, a car that will stop, so we need to upgrade the handling to match the capability of the rest of the car.

SUSPENSION

This car came w PASM (Porsche Active Stability Management), which also means it has electronic shocks. When upgrading the suspension, all elements were under consideration (shocks (mechanical, or electronic), springs, control arms, bushings, and sway bars. The big decision was relative to the shocks….stay w the stock PASM, and just implement a DSC controller, change to racing electronic shocks w an electronic controller, or switching out and going the traditional route of some form of mechanical shocks (single, dual, triple, quad adjustable, with or without remote reservoirs). The things you can do w electronic shocks and electronic shock controllers opens up such other worlds that are now possible, things you can’t accomplish w just pure mechanical shocks.

So, the decision was made, going w both upgraded electronic shocks, and an upgraded and software controlled DSC controller. At the highest level of electronic shocks, there are not a lot of high end systems…..yet. We decided that Tractive coil-overs would be the best choice, as they were also well understood by the creators of the DSC controller, and had been integrated and tested together.

The Tractive coil-overs come w a front adjustable camber plate. That would allow us to dial in the front alignment specs we desired. The normal approach to do this on 911’s is to add GT3 like 2-piece front lower control arms. We wanted to have as much adjustment as possible in the suspension, and as little defection in the suspension as well. That is usually a hard decision. In a race car, everything in the suspension relative to connecting points is solid. No deflection at all. Provides great touch, sensitivity, reaction to any input from the driver. Great connection between the driver and the car. However, solid suspension connections and / or bushings don’t hold up no matter how well designed or size on street use / abuse. This car is in the category of track car that you can drive on the street, so will not see lots of street miles, so the decision was made to go solid on the bushings, connecting points. Well then….as we have done in the other choices, we looked for the best possible set of control arms and monoball bushings. These are JP control arms, absolutely the best there is.

The final piece of the equation is then to dial this complex suspension in. Ride height, rake, camber, caster, toe, sway bar settings, electronic shock settings, DSC settings….and we have one amazing car.

Goal achieved…this car can certainly take it to the GT3’s. The car brings massive smiles to the customer, and when driving is a JOY, it’s a JOY to be driving.

BRracing – bringing JOY to our customers