APEX introduces several new FORGED wheels. These are new and improved versions of many of their classic flow form wheel designs, but now fully FORGED. Beautifully crafted details, exclusive finish options, plus all the features APEX is known for.

“I” BEAM SPOKES

One of the most significant upgrades to the forged wheels is the addition of “I” beam spokes. Any excess material that doesn’t add strength is carved out from the sides of the spokes using a precision CNC ball cutter. This process is often deemed cost-prohibitive by other wheel manufacturers, but for true performance without compromise, this is APEX implemented.

STRONGER WHEELS

Want to know how strong a wheel is? Look at the load rating. Many wheel manufacturers simply rely on the word “forged” to imply strength when their actual load ratings are just as low as cast wheels. APEX wheels were designed from the start to have measurably higher load ratings so they don’t just sound stronger, they are stronger. To make these the strongest wheels they could, they applied higher pressure during the “forging” process, using 10,000 ton forge. This extreme pressure increases the strength of the aluminum by eliminating porosity and improving the grain structure.

BIG BRAKE CLEARANCE

The APEX forged wheels improve on the well known design of their “flow form” wheels to create even larger brake clearance thanks to their high- clearance barrel design. Forging allowed them to reduce the spoke thickness to create new spoke profiles without compromising strength.

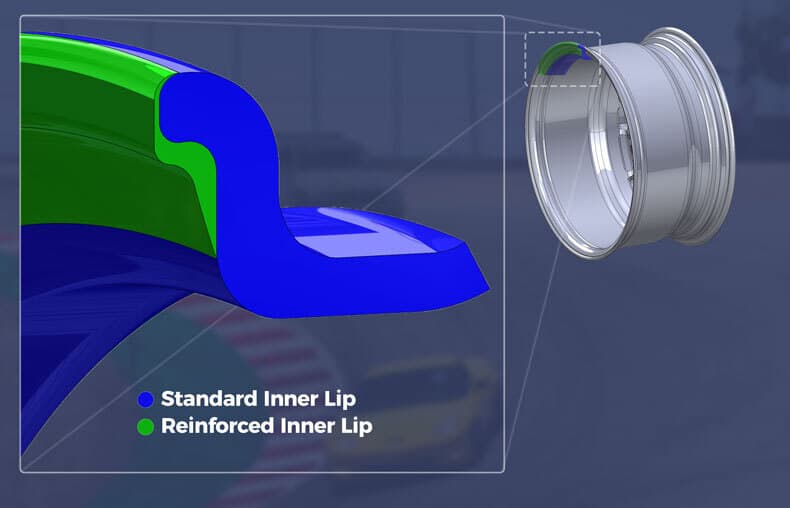

BIGGER, TOUGHER INNER LIP

The inner lip is the most vulnerable part of a wheel, because it has no spokes for support. By using 6061-T6 aluminum, and reinforcing this high-impact area with more metal, APEX provides an extra layer of protection against track berms, potholes, and whatever else the road may throw at you.

PAINTLESS KNURLED INNER BEADS

Whether it’s a day at the track or months of street driving, repeated hard braking can make a tire slip along the bead seat area, and cause the tire / wheel to go out of balance. Knurled beads help, especially when left unpainted, maximizing grip.

BUILT FOR IMPACT SOCKETS

Track wheels need to be able to use track tools. Don’t settle for wheels that require undersize “tuner” lugs or thin walled sockets. All APEX wheels accomodate over-sized race lugs and impact sockets to make changing wheels lightening fast.

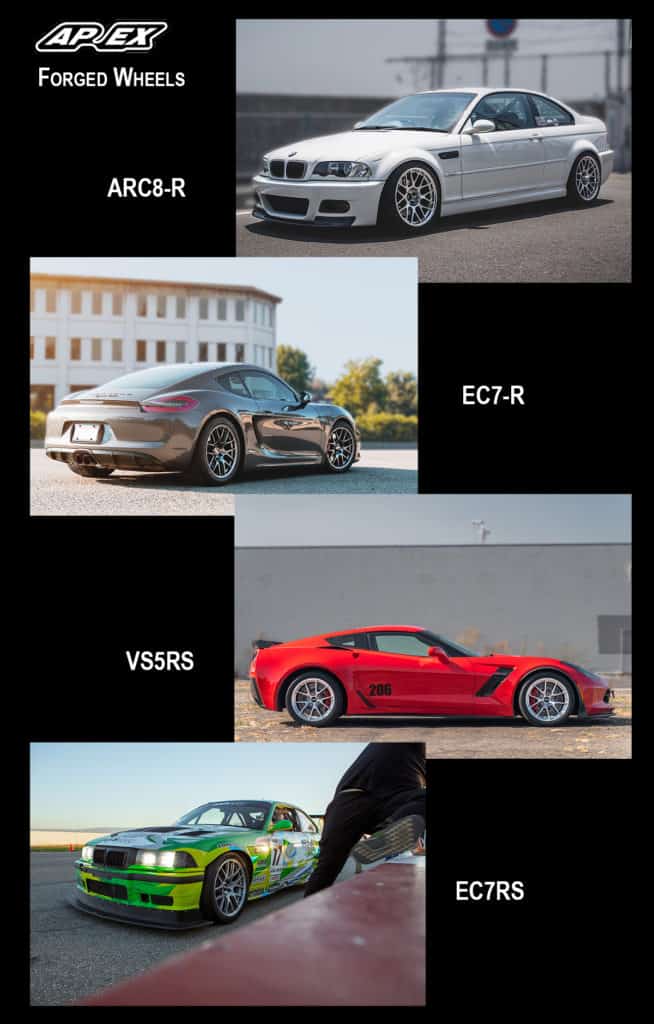

APEX FORGED WHEEL PORTFOLIO

APEX ARC-8R FORGED

Now enhanced with all the added benefits of forged manufacturing. The ARC-8R is a significantly stronger version of our most popular ARC-8 flow formed design.

- Forged 6061-T6

- Significantly Stronger

- Increased Caliper Clearance

- Paintless Knurled Beads

- Premium Finishes

- Lifetime Structural Warrenty

- Available in 17″, 18″, and 19″

APEX EC-7R FORGED

Their new EC-7R is a significant step forward. Now both lighter and stronger than the original flow formed version thanks to “I” beam spokes and forged manufacturing. It’s enhanced with the features and benefits we have been waiting for from Apex.

- Forged 6061-T6

- Significantly Stronger

- Increased Caliper Clearence

- Paintless Knurled Beads

- Premium Finishes

- Lifetime Structural Warrenty

- Available in 17″, 18″, and 19″

APEX VS-5RS FORGED

- Forged 6061-T6

- Significantly Stronger

- Increased Caliper Clearence

- Paintless Knurled Beads

- Premium Finishes

- Lifetime Structural Warrenty

- Available in 17″, 18″, and 19″

Available in a wide variety of finishes, colors:

BRRacing- Always pushing to stay ahead.